Equipment List

CNC Mill Specs

Technical Specifications: PCNC 1100 Series 3 CNC Mill

| Key Dimensions/Weight | |

|---|---|

| Table Size: | 34″ x 9.5″ |

| Table Slots: | 3 Slots 5/8″ |

| Travel: | 18″ x 9.5″ x 16.25″ (X,Y,Z) |

| Spindle Nose to Table: | 17″ maximum |

| Spindle Center to Column: | 11″ |

| Spindle Nose Diameter: | 3 3/8″ |

| Shipping Dimensions: | 56″ x 45″ x 60″ |

| Weight: | 1130 lbs net / 1296 lbs gross (excludes stand) |

| Max Workpiece : | 500 lbs Maximum |

| Power | |

|---|---|

| Power Requirements: |

|

| Iron | |

|---|---|

| Frame and Table | Cast iron frame and table, with hand scraped hydrodynamic ways and tapered adjustment gibs |

| Way Surfaces | Low friction PTFE-filled Acetyl bonded sliding surface. Similar to Rulon® and Turcite® |

| Spindle | |

|---|---|

| Spindle Taper: | R8 (optional BT30 retrofit available) |

| Spindle Construction: | Cartridge with spindle lock |

| Spindle Drive: | Emerson Control Techniques™ Sensorless Vector Technology with Fold-back logic |

- 1100W continuous, 2800W peak. Learn More

Spindle Power:1.5 hp Brushless AC 3-phase Induction Motor, Vacuum Pressure Impregnated (VPI) WindingsSpindle Speed:100 to 5140 RPMTransmission:V-Belt Drive, 2 ratios

| Motion | |

|---|---|

| Feed Rate: | 110 IPM (X,Y) 90 IPM (Z) |

| Axis Drives: | High Performance Polyphase Stepper Motors with Leadshine® Microstepping Drivers. – Learn More |

| Ballscrews | Ground P4 Ball Screw with anti-backlash double ball nut

|

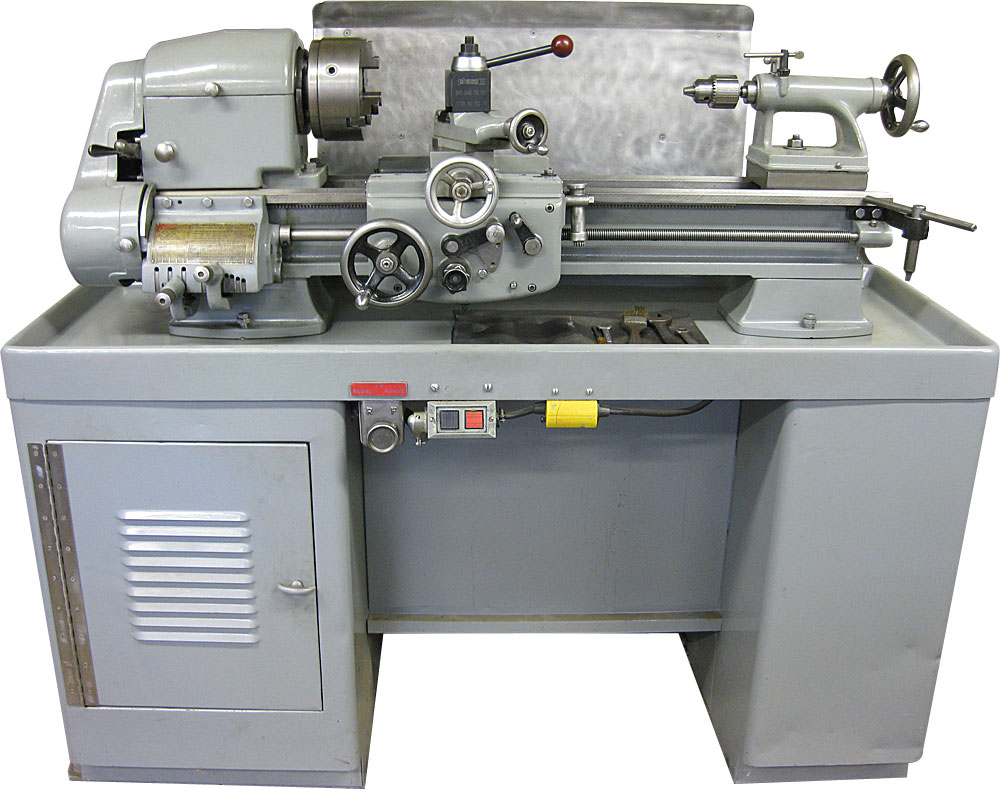

Logan Lathe

Technical Specifications: Logan Lathe

CAPACITY Of LATHE

Swing over bed and saddle wings ……………………… 11 1/8”

Swing over saddle cross slide screw cutting lathes ……. 6 1/8“

Swing over saddle cross slide turret lathe …………….… 4 1/2“

THREADS AND FEEDS

Quick change gear box and automatic apron

Worm drive from lead screw spline for power feeds

Friction clutch on power feeds

Longitudinal feed .0018” to .1000” per spindle revolution

Cross feed .25 times longitudinal feed

Half nut drive from lead screw thread for thread cutting

Threads-48 selections RH or LH-4 to 224 per inch

Lead screw diameter and threads per inch 3/4”-8

BED

Width of bed across way ………………………………… 6-15/16”

Length ……………………………………….… 43 1/8” and 55 1/8“

Precision ground ways; 2 prismatic ”’V” ways and 2 flat ways

HEADSTOCK AND SPINDLE

Spindle Bearings: Sealed New Departure Ball Bearings. precision type with preloading

Hole through spindle-1 3/8“

Draw·in collet capacity …………………………………………… 1″

Spindle Nose Diameter and threads per inch: 2 1/4”-8”

Width of face of bull gear and back gears: 3/4”

Face plate diameter: 6″

Number of spindle speeds: 16. 45·1500 rpm

CROSS SLIDE AND COMPOUND REST, SCREW CUTTING LATHE

Cross Slide Travel 6 1/4”

Cross Slide graduated in thousandths

Cross feed screw mounted on self lubricating bronze bearings

Compound Rest Travel 2 1/4“

Compound rest graduated in thousandths

Compound swivel graduated 90° in both directions

Tool post opening for tool holder shank 3/8” x 3/4”

Size of cutter bits used-1/4” sq.

TAILSTOCK

Spindle Travel: 4”

Spindle Gradations: 1/16”

Morse Taper center: No. 2

Tailstock set-over for taper turning: 11/16”

MOTOR

Use 3/4 HP, 1750 RPM Motor

Millermatic 185 Mig Welder

Rated Welding Output: 150 A @ 23 Volts DC, 60% Duty Cycle

Amperage Range: 30 – 185

Maximum Open-Circuit Voltage DC: 33

Amperes Input at Rated Load Output, 60 Hz, Single-Phase:

200 V: 30 (1.6)*

230 V: 26 (1.4)*

KVA: 6 (0.27)*

KW: 5 (0.13)*

Weight: 165 lb (75 kg)

Overall Dimensions:Length: 36 in (915 mm), Width: 18 in (457 mm), Height: 27 in (686 mm)

Wire Type And Diameter:

Solid Steel / Stainless Steel: .023 – .035 in (0.6 – 0.9 mm)

Flux Cored: .030 – .045 in (0.8 – 1.2 mm)

Aluminum: .030 – .035 in (0.8 – 0.9 mm)

Calculated Wire Speed Range At No Load: 138 – 795 IPM (3.5 – 20.3 m/min

Max Wire Feed Speed While Welding: 650 IPM (16.5 m/min)

Operating Temperature Range: –20C to +40C

Storage Temperature Range: -30C to + 50C